The following information relates to all hot adhesive machines that require manual filling

Filling a Hot Adhesive Tank

An overfilled hot adhesive tank could cause severe burns to operators, supervisors or service

personnel.

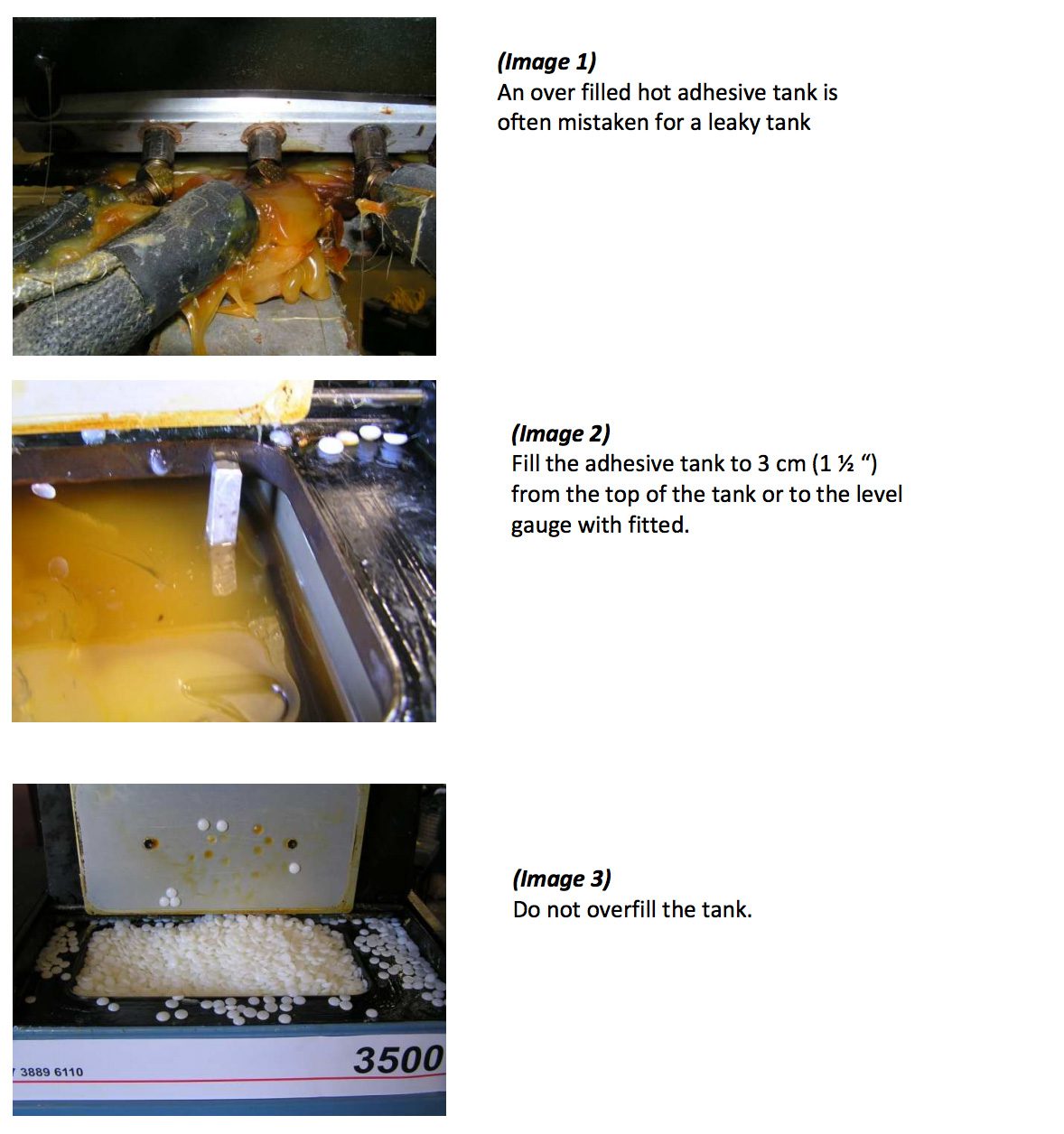

An over filled hot adhesive tank is often mistaken for a leaky tank (refer image 1)

The correct procedure to fill a hot adhesive tank is as follows

- Wear safety gloves, safety eyewear, clothing covering exposed skin and safety footwear.

- Use only a hot melt adhesive product as recommended by your hot melt adhesive supplier.

- Do not fill a not melt tank which is at or above face level.

- With the melter at operating temperature, open lid assembly allowing access to the

adhesive tank. - Check the glue level

- Only add adhesive to the hot adhesive to the hot melt adhesive tanks if the tank is half empty or below. Do not add adhesive to the tank that is greater than three quarters full.

- If the hot adhesive tank requires filling use only a metal scoop or ladle with a heat resistant handle.

- Fill the adhesive tank to 3 cm (1 ½ “) from the top of the tank or to the level gauge where fitted (refer image 2). Do not overfill tank. ( refer image 3)

| WARNING - Do Not |

|---|

| Use your hands to fill the hot adhesive tank |

| Use plastic cups, cut down drink containers, food containers or polystyrene cups. These products can melt when contact is made with hot adhesive and under extreme conditions could cause the hot adhesive and under extreme conditions could cause the hot adhesive tank to vent gas and hot adhesive under extreme pressure. This condition poses a high risk of serious burns and / or death. |

| Use cardboard cups, boxes of trays |

| Allow water or drinking liquids to come in contact with hot adhesive. Water can hot adhesive react violently when mixed, increasing the risk of serious burns |

Filling Hot Melt Tanks